Reverse Engineering Solutions

For more than 30 years Winslow has been at the forefront of mitigating obsolescence through the re-manufacture of legacy components. We are fully at verse with the primary requirement to create form, fit and function articles that meet the material and surface treatment of those used in the original specification and testing. We are also…

Injection Moulding

Winslow are your technical experts for bespoke plastic injection moulding, providing a wealth of knowledge. Our mould shop is run by our toolmakers, adopting a total understanding across the tool and moulding relationship to ensure an extended tool life. With a rich history in producing bespoke technical mouldings to various industries, we are able to process a wide range of thermoplastic materials, including high engineering grades.

CNC Machining

CADCAM and Conversational programming allows us to quickly manufacture parts from your 3D files, 2D dxf files or hard copy drawings. Our CAD Team is available for when you require design assistance and prototyping for development.

Toolmaking

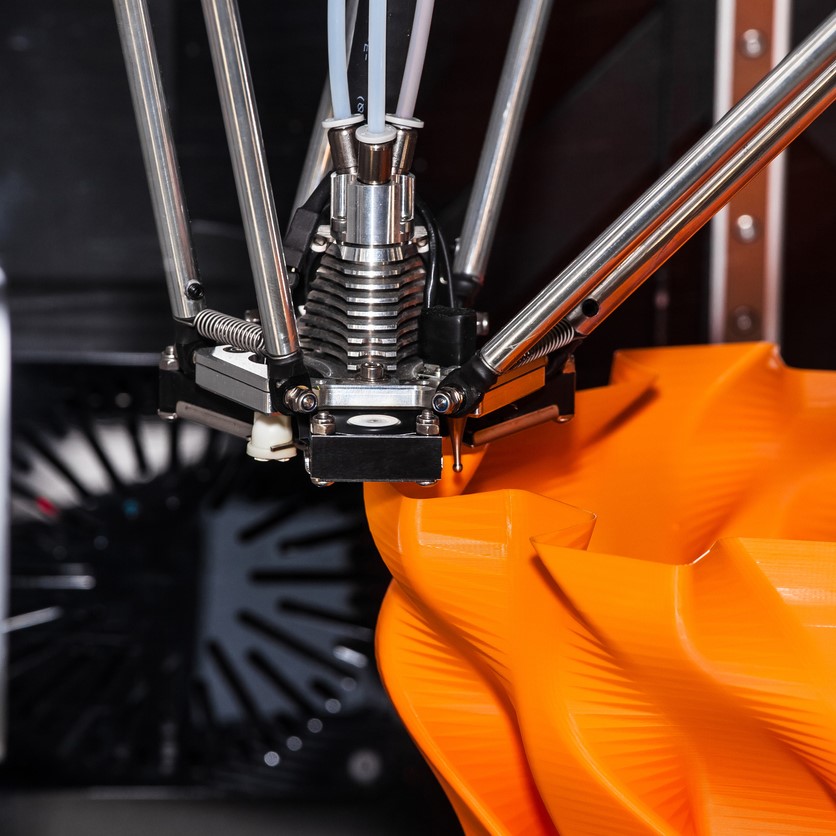

Winslow has a fully equipped Toolroom and has been manufacturing injection mould tooling since 1982 for both our own products and those of our customers. From fully hardened, hot feed multi-cavity to aluminium or 3D printed cold feed tools, we are here to advise and ensure you meet your tool life, delivery and budget requirements. Talk to us also if you require assistance with the design and manufacture of Jigs and Fixtures to aid manual or automatic assembly lines.